Disregarding the discussion about why we needed a video doorbell, after several weeks of planning and investigating I thought I had arrived at a reasonable solution to installing my VTO2311R-WP. As you can see from this photo, the front door has sidelights and the optimal location is on the door trim where the blue tape is attached:

The optimal wire run would have been would have been to drill through the bottom plate, but beneath those trim pieces on either side are three 2x6's sistered together with Lord only knows how many nails.

So I came up with a solution that was working quite well. I routed a 1/4" slot on the side edge of the trim - the trim is one inch thick cedar, so there was plenty of width and depth. I build a little routing rig

and routing the slot was straightforward:

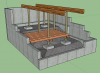

I then drilled down through the trim at an angle and through the decking into a ledger board (the front porch is just a deck) with an 18" long 1/4" bit. I had measured pretty well and found where

the drill bit enter the ledger board and used a forstner bit to give myself a little room to find the hole:

The optimal wire run would have been would have been to drill through the bottom plate, but beneath those trim pieces on either side are three 2x6's sistered together with Lord only knows how many nails.

So I came up with a solution that was working quite well. I routed a 1/4" slot on the side edge of the trim - the trim is one inch thick cedar, so there was plenty of width and depth. I build a little routing rig

and routing the slot was straightforward:

I then drilled down through the trim at an angle and through the decking into a ledger board (the front porch is just a deck) with an 18" long 1/4" bit. I had measured pretty well and found where

the drill bit enter the ledger board and used a forstner bit to give myself a little room to find the hole:

... and then cheerful Mr. Murphy arrived. I placed the bit in the hole with the drill still attached and went under the deck to see how deep I had to drill into the ledger board to expose the full

width of the 1/4" hole. I guess I should have locked the front door or something because my wife opened the door, stepped out and kicked the drill with bit attached. I heard a loud "PIIIIING" and

well, the title of this post says it all. The bit broke where the fluted part of the drill starts, so the broken part in the wall is four inches long.

I have put all my eggs in this edge routing installation and I have got to figure a way to clear that broken bill from the hole. The bit is somewhat loose, that is, I can rotate it and push it up and down a little with vice grips. My options as I see them:

Option #1) Expose (by tapping from above) approximately 1-inch sections of the bit, attempt to cut them (I know, I know - it's a drill bit), and repeat until hole is clear. Does anyone believe that a carbide cutter in a reciprocating tool would cut that bit? I am not optimistic, but I have not tried... well, to say it another way: I have not tried ruining a $20 blade to find out. I might be able to get an angle grinder up there. I tried to break the bit with a cold chisel and hammer, but that did work.

Option #2) Drill up from the bottom of edge of the ledger board (with a slightly larger diameter bit) and basically create a conduit to drive the bit out from the top. I am worried about getting the angle correct, but seems possible.

Any help or suggestions would be appreciated!

In case anyone is wondering:- I have ripped a thin strip of cedar spine that will fit snugly back into routed slot so the Cat5e UTP will not be exposed as shown in the photos. I bench checked the slot and spine and also found that if I placed

a thin layer of silicone caulk over the spine and press a scrap of cedar against it, the texture is transferred and after painting it is difficult to see unless you know exactly what to look for. - I just noticed an optical illusion: my thumb is no where near the router bit in that one photo.

- The front door picture is poor in that it does not show that above those top sidelights there is several feet of wall. From the doorbell height to the top plate is 76 inches, another 12 inches of engineered joist, and then two more top plates providing some framing support that I do not understand. Plus, almost all the front exterior lighting wiring is stapled on top. Beyond an amateur like me.

- I tried with the bucket and 2x4 rig to test the placement on the left wall, but at any reasonable angle the camera faced directly into the sun and it was unacceptable. There is a IPC-T5442T-ZEB covering the porch and front door about 15 feet to the left.